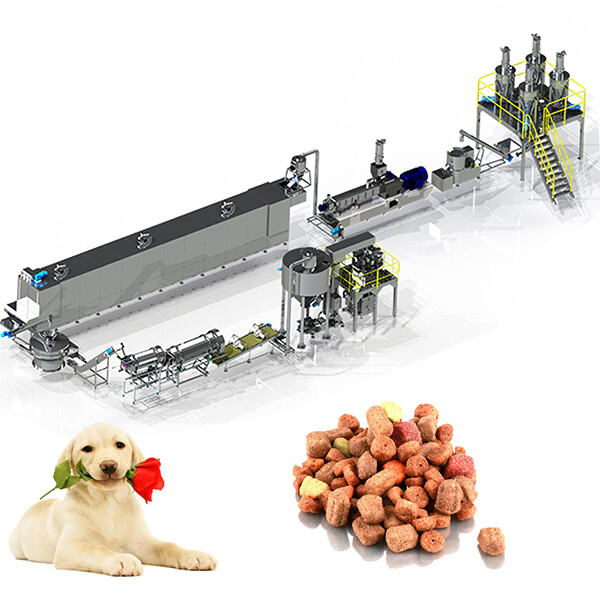

Αυτό είναι ένα από τα μηχανήματα προβολέων που έχουμε, Μηχανή που μαγειρεύει γεύματα για τη γούνινη οικογένειά μας! Μειώνουν το χρόνο στην επεξεργασία των τροφών για κατοικίδια. Σήμερα, θα συζητήσουμε συγκεκριμένα πώς βοηθούν στη διατήρηση του χαμόγελου στους τετράποδους φίλους μας

Η κατασκευή του θερμοδιακόπτης ACh έχει πολύ διαφορετικά μηχανήματα. Για παράδειγμα, ένα από αυτά μπορεί να προετοιμάσει πρώτες ύλες (κρέας ή λαχανικά) σε σβώλους κροκέτες: τα αποξηραμένα τρόφιμα προσλαμβάνονται περισσότερο. Στη συνέχεια, όμως, έχετε άλλα μηχανήματα που έχουν σχεδιαστεί για να αναμειγνύουν όλες τις γεμίσεις μεταξύ τους, αν πρόκειται για κονσέρβα. Αυτό περιλαμβάνει τη διατροφή ενός μεγάλου αριθμού κατοικίδιων ζώων, καθώς εξοικονομούν πολλά από αυτά όπου χρειάζεται λιγότερος χρόνος για να παραχθεί τεράστια τροφή. Αλλά αυτό κάνει λιγότερο χρόνο για να αναπτυχθεί πολύ περισσότερη τροφή, άφθονες προμήθειες από τις οποίες απαιτούνται για να ταΐσουμε όλα τα κατοικίδιά μας

Η τροφή για κατοικίδια είναι οι ίδιες διαδικασίες που χρησιμοποιούν μηχανήματα υψηλής τεχνολογίας για την παρασκευή τροφών για σκύλους και γάτες, ενισχυμένα θρεπτικά συστατικά σε μικροσκοπικά αποξηραμένα κομμάτια ουρανού σε σχήμα ψήγματος για το κατοικίδιο ζώο σας. Για παράδειγμα, ορισμένες συσκευές δημιουργούνται με μοναδικούς ανιχνευτές ικανούς να αναγνωρίζουν τα επίπεδα στα τρόφιμα, αποτρέποντας οποιοδήποτε επιβλαβές ή επικίνδυνο υλικό. Και μας ενδιαφέρει πάρα πολύ, καθώς προφανώς, η ποιότητα για τα κατοικίδιά μας είναι πολύ σημαντική. Δεν πρόκειται να φτύσει α διακόπτης θερμοστάτη εναλλασσόμενου ρεύματος, απλώς θα σταματήσει αν κάποιος δοκίμαζε προφανώς κάτι κακό. Μια πτυχή αυτού είναι να προσέχουμε την ευημερία στα σπίτια μας, συμπεριλαμβανομένων των κατοικίδιων

Παραγωγή τροφών για κατοικίδια- Αυτοματοποίηση στην παραγωγή τροφών για κατοικίδια: Τα ρομπότ αντικαθιστούν τη χειρωνακτική εργασία για την παρασκευή ή την επεξεργασία αυτών των τροφών για κατοικίδια. Παλαιότερα οι Humans είχαν συσκευάσει και ετοιμάσει το φαγητό. ac αλλαγή: αντί για ανθρώπους που θα χρειαζόταν να μαζεύουν τα τρόφιμα. Αυτό είναι καλό καθώς απελευθερώνει μέσω των επεκτάσεων όπλων ενός ατόμου την κυριαρχία για εσάς σε μικρόβια ή ίσως χώμα που μένει στα γεύματά σας. Τα μηχανήματα μας επιτρέπουν να διατηρούμε τα τρόφιμα καθαρά και ασφαλή για τα κατοικίδια μας

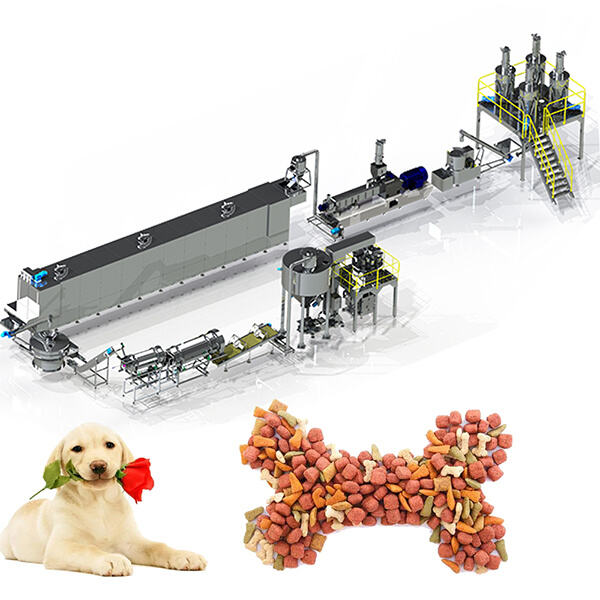

Οι νεότερες μηχανές τροφών για κατοικίδια Jinan MT διαπρέπουν επίσης στο να μοιράζουν τα συστατικά με μεγάλη ακρίβεια. Αυτό είναι ιδιαίτερα εφαρμόσιμο, καθώς βοηθά στη χρήση των σωστών ποσοτήτων όλων των συστατικών, ώστε να είναι κορυφαία ποιότητα adδικαιολογήσιμο δι μπορεί να κατασκευαστεί, η πολλαπλή χρήση επιτρέπει την ποσοστιαία αναλογία πρώτων υλών να κυμαίνεται από 20:1 και επίσης διατηρεί μια καλά ισορροπημένη διατροφή με έξυπνες τεχνολογίες. ακριβής δοσολογία με την εισαγωγή παραμέτρων εισαγωγής σε μια διαδικασία, π.χ. μηχανές έγχρωμης όρασης κ.λπ., που κάνουν τα κατοικίδια ζώα γρήγορα. Αυτό σημαίνει ότι τα κατοικίδιά μας λαμβάνουν ισορροπημένη διατροφή με κάθε τροφή που τους σερβίρουμε και μπορούν να είναι υγιή, δυνατά ζώα όταν λαμβάνουν τα σωστά θρεπτικά συστατικά που χρειάζεται το σώμα τους

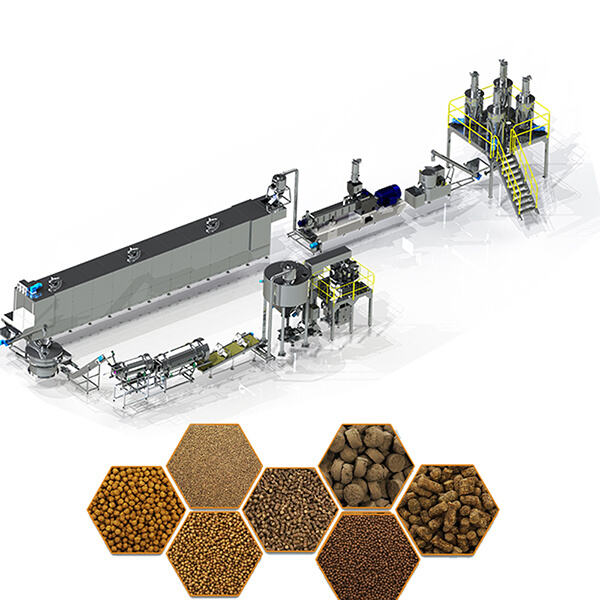

Τα τρόφιμα για κατοικίδια Jinan MT παράγονται χρησιμοποιώντας μηχανήματα αιχμής για τη μείωση της χρονικής περιόδου παραγωγής, δημιουργώντας μεγαλύτερο όγκο προϊόντος που μπορεί να δημιουργηθεί πιο γρήγορα. Και είτε το πιστεύετε είτε όχι, ένα από αυτά τα μηχανήματα μπορεί να παράγει 2,000 λίβρες την ώρα!! Είναι πολύ φαγητό. Έχουμε άπειρη προσφορά μεταλλικός διακόπτης θερμοστάτη για όλα τα κατοικίδια ζώα μας κυρίως επειδή παράγεται τόσο γρήγορα. Φυσικά πρέπει να φάει και το μικρό μας πέτα

Ο εξοπλισμός μας έχει χτίσει μια ισχυρή αναγνώριση στην αγορά. Παρέχουμε υπηρεσία κλειδί στο χέρι, από την προετοιμασία πρώτων υλών έως τη μηχανή παραγωγής τροφών για κατοικίδια, με σύστημα ελέγχου MCC. Ολόκληρη η γραμμή διαδικασίας είναι εξαιρετικά υψηλός βαθμός παραγωγικότητας και αυτοματοποίησης. Η προσαρμογή βασίζεται στις ανάγκες του πελάτη.

Η MT machinery παρέχει υπηρεσία μεταπωλήσεων μηχανών παραγωγής τροφών για κατοικίδια σε διεθνείς πελάτες, συμπεριλαμβανομένων γρήγορων απαντήσεων, ομαλή σαφή επικοινωνία, τεχνική υποστήριξη, διασφαλίζοντας ότι τυχόν ζητήματα επιλύονται αποτελεσματικά έμπειρη ομάδα βοηθά με το χέρι σε τυχόν προβλήματα ερωτήσεων παρέχοντας γρήγορες αποτελεσματικές λύσεις προληπτική υπηρεσία προσέγγισης οδήγησε εντυπωσιακή αύξηση της ικανοποίησης πελατών παγιωμένη φήμη αξιόπιστη συνεργάτης διεθνές εμπόριο MT Machinery δεσμεύεται να παρέχει την υψηλότερη δυνατή εξυπηρέτηση πελατών με επίκεντρο τις ανάγκες διατήρηση των καναλιών επικοινωνίας ανοιχτά δέσμευση εξαιρετικές υπηρεσίες μετά την πώληση όχι μόνο βελτιώνει την αγοραστική εμπειρία των πελατών αλλά βοηθά στη δημιουργία μακροχρόνιων σχέσεων συνεργασίας τους

Με περισσότερη από την εμπειρία των μηχανών παραγωγής τροφίμων για ζώα συντροφιάς της ομάδας μηχανικών μας, διαθέτουμε πολλές πατέντες που αφορούν ειδικά μηχανήματα διέλασης τροφίμων και έργα όπως σύστημα ξήρανσης πολλαπλών επιλογών, χαμηλής έντασης ενέργειας, συστήματα εξώθησης τροφίμων υψηλής ακρίβειας και ένα μοναδικό μηχάνημα εξομάλυνσης καλαμποκιού πλήρως αυτοματοποιημένο σύστημα στοίβαξης και συσκευασίας κ.λπ. Προσφέρουμε φόρμουλες παραγωγής, εγκατάσταση, εντοπισμό σφαλμάτων και υπηρεσία εκπαίδευσης χειριστή μέχρι να βεβαιωθούμε ότι μπορεί να κατασκευαστεί το προϊόν. Σε σύγκριση με τους ανταγωνιστές μας, το προϊόν μας προσφέρει την υψηλότερη απόδοση, εξοικονόμηση ενέργειας ανώτερη ποιότητα, ανταγωνιστική τιμή, και ολοκληρωμένη εξυπηρέτηση πριν και μετά την πώληση.

Ένα στιβαρό μηχάνημα παραγωγής τροφών για κατοικίδια, μια μεγάλη παραγωγική ικανότητα και ένα ευρύ φάσμα εξοπλισμού διέλασης για τρόφιμα είναι όλα πλεονεκτήματα. Ευέλικτο και ικανό να προσφέρει συγκεκριμένες υπηρεσίες. Ακριβή και αυστηρά πρότυπα και μηχανισμοί ελέγχου.