The pet food making machine is so important because it helps prepare a diversified and healthy range of products for our beloved pets. Just as we need wholesome meals to keep us going strong, our furry friends also require safe and healthful fare. That is why it really important for pet owners to make sure that the food they are feeding to their furry buddy should be tasty as well as safe and healthy.

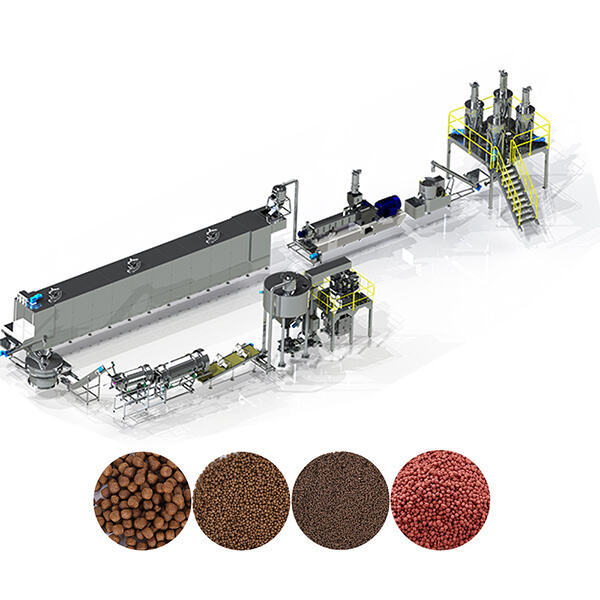

Put simply, a Jinan MT pet food processing line is group of machines that are interconnected to produce dog or cat foods. It is like a gang of helpers, each with some work to be done. Those ingredients, like meat, grains and vitamins in different measurements all go into these machines to mix it up and make for the pet food product we see in bags or can. Each type of pet food requires a range of ingredients and the correct dog food making machine. For instance, how moist food is made should not be the same as when dry food is being produced because of course wet has more moisture. Therefore, the machines and how we combine treatments will also differ.

For us to have safe pet food, there are many things that must take place. First, pet food manufacturers should guarantee that all of their ingredients are obtained from safe origination points. That is, The Ingredients must be Pure and Free of Harmful Chemicals and Germs that could Cause illness to your pet. Our side of the equation reminds food must be processed in Jinan MT machines free from anything toxic. This is really critical particularly as germs machines can also compromise the food safety. That food also has to be tested after it 's processed to make sure its safe for pets. If we use all of these steps in collaboration, our pets can be safe and healthy. With proper oversight over such processes, pet food makers will keep our companion animals safe from harm.

Of course, technology also has a huge part in making pet food. The machines, of course make them a more productive pet food manufacturer. They use technology to make the pet food at high-speed and in large quantities. This is why exact machines and the ability of them to work in harmony together are qualities needed. Pet food production also uses some ground machine: choppers that form the base, mixers to ensure uniform mixing of components and ovens in which feed is cooked. Some other dry dog food making machine could be used also, depending on what kind of pet food is being made and/or the final presentation (formulation or type), such as shaping machine or packaging. Not only does this technology use allow the process to speed up, it can also guarantee a perfect repeatable product every time.

This is important since our needs are different and same goes with Pet Nutritional Needs — it changes according to age, size, health. Other dogs might require more protein to ensure they grow big and strong, or have enough carbs for energy in order to run around the yard all day. Pet food companies need to make sure that their products can provide these varied needs. For instance, some pet foods may be made to high-protein specifications (which is brilliant for exuberant dogs and cats) Most other pet foods have more carbohydrates because low activity pets do not need the extra energy. To ensure all pets receive the type of food they need to thrive and be happy.

THE SCIENCE BEHIND MAKING PET FOOD: a suit of processes, making pet food is complex, with so many steps to be covered. It begins with selecting ingredients that are safe. In such scenarios, they need to opt the with accordance of right ingredients and this must be assembled having a help of machines like from Jinan MT. Which makes sure everything is mixed well together. The pet food is then formed into the proper shape, cooked to kill bacteria like salmonella (although not always successfully), and packed for sale. Step by step each of these processes become very important in ensuring the safety and quality of pet food. This entire dog food processing machine process is a meticulous art that should be followed with great precision and kept little room for any bad-quality dog food.

Our machine has achieved a Pet food processing line standing in the marketplace. We provide a turnkey service, from raw material processing to packing system, which includes MCC Control System. The entire process line is significant automation and energy efficiency. Any requests of the customer can be met.

Pet food processing line robust supply chain, an enormous capacity of production, and a selection of extrusion machineries for food are all strengths. We can provide customized solutions and a lot of flexibility. Set up independent, stringent standards and auditing procedures.

With more than 20 years of engineering experience, we have several unique patents related to food extrusion equipment and projects that include a multi-choice Pet food processing line drying system, high-precision food extrusion systems and a unique corn flattening machine with a complete automated packing and stacking system etc.We can offer formulas for production Installation and debugging assistance along with operator training, until products are manufactured to your satisfaction.Our solution has superior quality and value, as well being high in efficiency and energy savings.

MT machinery provides Pet food processing line after-sales service international customers including prompt responses smooth clear communication technical support ensuring any issues resolved efficiently experienced team is hand assist any inquiries problems providing swift effective solutions proactive approach service has led impressive increase satisfaction customers consolidated reputation trusted partner international trade MT Machinery committed providing highest possible service support customers focusing needs keeping communication channels open commitment exceptional after-sales services not only improves buying experience customers but helps build long-lasting relationships cooperation them