Raw materials: Using corn starch, tapioca starch or potato starch as the main raw materials, and is transformed into a gel state of super-heated rheo-logical variant through the combined action of high temperature, high pressure and shear force in the puffing equipment, and obtain a large amount of energy, change its original physical and chemical properties,α-form starch structure, and finally produce modified starch (pre-gelatinized starch) products.

Application: This production line can make modified Starch, denatured starch by changing different designed barrel and screw of double screwextruder. Modified starch is widely used in textile, food process, oil drilling, paper, construction industries etc.

Capacity: 100-1500kg/hr

Features:

Features:

1) Special mixing shaft and blade design, efficiently improve cook degree and mix raw materials uniformity.

2) High level water resistance reduce feed waste, which reduce FCR and digest better.

3) High automation and intellectualize.

4) Adopting advanced world famous brand components , such as electric parts, Pneumatic parts and operation parts.

5) Simple structure in linear type, easy in operation, installation and maintance.

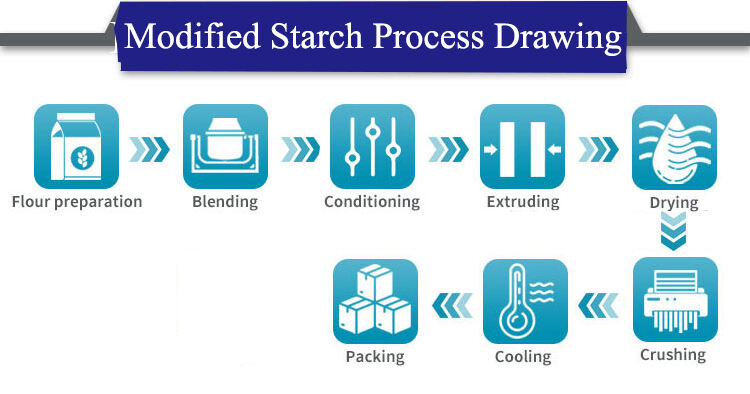

Flow chart of Oil drilling starch extruding plant:

With OEM and ODM design, we promise to offer customers suitable proposal according to his factory size, which includes factory layout, Production line drawing, Turn-key solution from material grinding to final packing system.

Technical Parameters of starch extruding line:

| Model | Starch extruding line MT85 | Starch extruding line MT100 | Starch extruding line MT110 | Starch extruding line MT135 |

| Installed power | 90KW | 180KW | 200KW | 240KW |

| Power Consumption | 63KW | 120KW | 150KW | 165KW |

| Capacity | 100-200KG/Hr | 500-600KG/Hr | 600-800KG/Hr | 1000-1500KG/Hr |

Oil drilling starch extruding plant samples:

Through changing the natural characteristics of natural starch by pre-gelatinization, this modified starch processing line is used to improve the properties of natural starch, expanding starch application range scope: physical, chemical and/or enzymatic treatments.

The final products characterizes by thermal viscosity, stability, freeze-thaw stability, gel strength, film-forming properties, transparency etc. Which makes it much more suitable for industry usage.