Taste TestCorn flakes: For a fun, crunchy way to start your day. Have you ever stopped to consider what goes into creating these? Corn Flakes the flakes which comes from duh corn grains, processed to make into tasty cereal that we all eat every morning. The Jinan MT pet food making machine process that transforms your normal corn into the breakfast favorite of many people is amazing to read about.

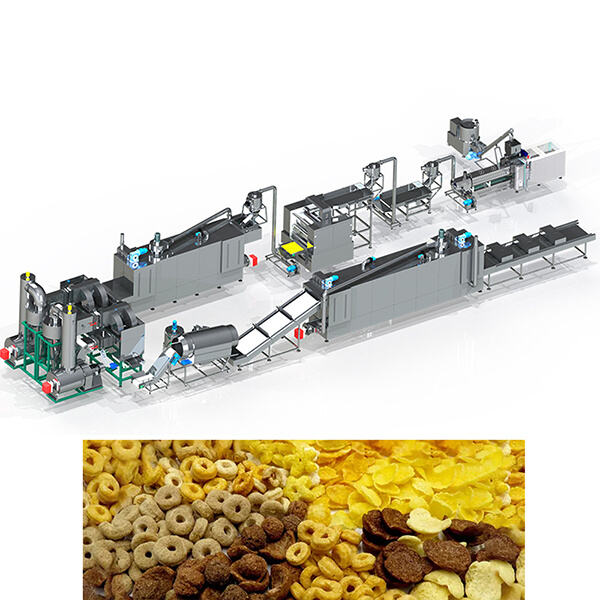

The corn flake factory is a very verve-esqe, exhilarated location. If you were walking in a corn flake factory, then when inside the whole thing would be just lots of Jinan MT pet food machine price and conveyors belts slightly bigger than your house working together to manufacture those yummy corn flakes. These jigs are used to help push the corn through various steps of processing. Everyone at the factory keeps a watchful eye to ensure that their corn flakes are completely safe for you to eat, and super tasty! They are very serious about their work because they want every bowl of corn flakes to be a source of home comfort for families.

The production of corn flakes is a fast process that benefits from advanced machinery. The Jinan MT dry dog food making machine in the factory whip round, doing exactly what machines are supposed to do and producing corn flakes quickly. To begin with, the corn grains are cleaned to remove any debris or unwanted granules. Good step, We do not want our corn flakes to be messy and unhealthy. Once clean, the corn kernels are taken and cooked until it is in a flake form that we all know. This process finally assures the production of toasted and packed corn flakes.

Special technology is used in the production of corn flakes to guarantee that this product will be really good. All steps are carefully controlled for optimal cooking of the corn flakes not too crunchy; not too soft. Jennie Schacht on January 06, 2010 at 11:27 AM. Packaging is also one important thing dog food making machine keeps the corn flakes well fresh and crispy. The corn flakes might go soggy, and no one likes eating cereal that is not crunchy.

To begin making the corn flakes recipe, start with cookingMaize kernels in boiled water. The corn grains are initially checked through cleaning in order to make them free from any unwanted particles which can deteriorate its taste. They are then boiled and cooled. Aftet that, the corn is cooked and ground down before being smashed into flakes and baked in a hot oven. dog food making machine price is this toasting step that also gives the corn flakes their delicious flavor and crunch. After we flaked out the cool flakes were then packed up and ready to be sent out into stores so that us Seawheeze goers can all enjoy it this year!

MT machinery provides Corn flakes production line after-sales service international customers including prompt responses smooth clear communication technical support ensuring any issues resolved efficiently experienced team is hand assist any inquiries problems providing swift effective solutions proactive approach service has led impressive increase satisfaction customers consolidated reputation trusted partner international trade MT Machinery committed providing highest possible service support customers focusing needs keeping communication channels open commitment exceptional after-sales services not only improves buying experience customers but helps build long-lasting relationships cooperation them

We have a 20-year Corn flakes production line and hold numerous patents for food extrusion machines and projects, including a multi-choice low-power drying system and patented high-precision extrusion system, patent-pending corn flattening equipment, patented fully automated packaging and stacking system.We can provide formulas for production installation and debugging and operator training, until you are completely satisfied with the products we produce. satisfaction.In comparison to our competitors, our product is high efficiency, energy-saving superior quality, competitive price, and a complete service prior to and after sale.

A solid supply chain, a huge capacity for production and a range of extrusion machines to make food are the main strengths. Flexible and capable of offering Corn flakes production line. They have strict and independent standards and audit methods.

Our machine has earned us a great recognition in the marketplace. We provide a Corn flakes production line, from raw material processing to packing system, which includes MCC Control System. The entire processing line has the highest level of productivity and automation. It is possible to customize the process according to customer's requirements.