Raw materials: Process for making artificial rice grains,comprises mixing rice flour,water and oil and cooking them in extruder,forming into rice-grain shape,drying and cooling in low temperature.The technique makes it feasible to avoid the loss of nutrition.

Application: with strong R & D ability, our engineers offer suitable proposal as customers' requirement, factory size, and local investment. This fortified rice production line can be used to produce artificial rice, fortified rice, konjac rice etc with various sizes as the moulds or dies changing of Twin Screw Extruder.

Capacity: 100-1000kg/hr

Features of fortified rice production line:

1) Large capacity;

2) Energy saving

3) Fully automatic PLC control system

4) Adopting advanced world famous brand components , such as electric parts, Pneumatic parts and operation parts.

5) Reasonable structural design, special material, self- cleaning performance and stability.

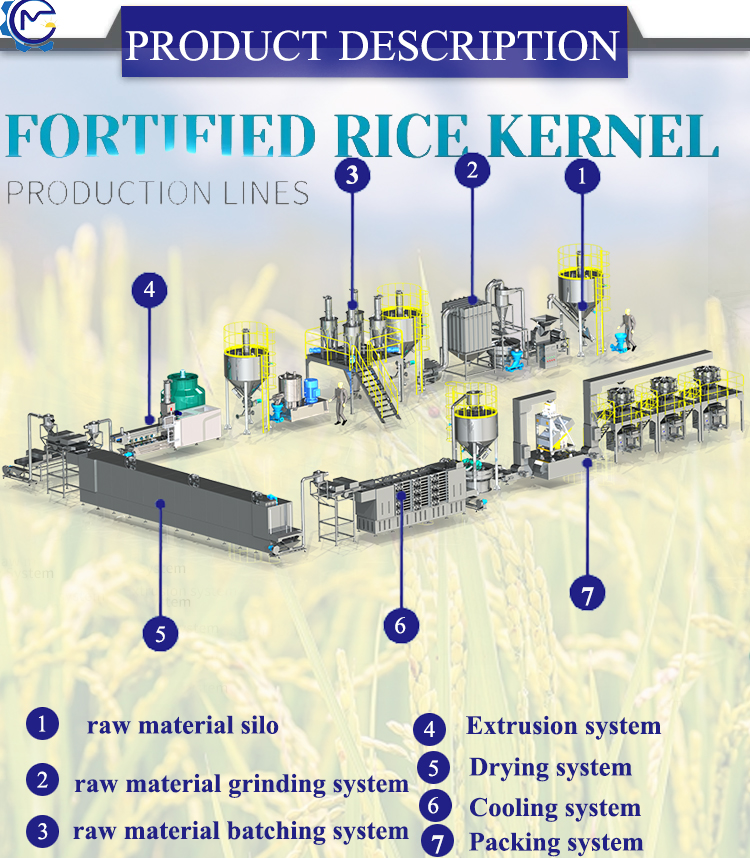

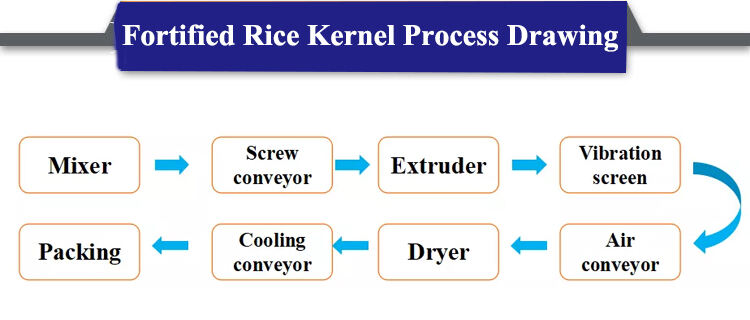

Process flow of fortified rice production line:

With OEM and ODM design, we promise to offer customers suitable proposal according to his factory size, which includes factory layout, Production line drawing, Turn-key solution from material grinding to final packing system.

Materials preparation--Material grinding--Material batching--Mixing--Extruding----Vibrating--Drying--Cooling--Packing

Technical parameters of fortified rice production line:

| Model | Installed power | Power consumption | Capacity | Size |

| MT65 | 85KW | 60KW | 80-100KG/HR | 28x1.2x2.2m |

| MT70 | 120KW | 85KW | 100-120KG/HR | 30x1.5x.2.2m |

| MT85 | 235KW | 165KW | 500-600KG/HR | 34x3.5x4.3m |

| MT75 | 180KW | 135KW | 300-500KG/HR | 32x3.5x4.3m |

| MT100 | 260KW | 195KW | 800-1000KG/HR | 36x3.5x4.3m |

Advantages of our fortified rice Extruder:

1) We will use intelligent Smart 2.0 Siemens control system, which is much more accurate, efficient than other traditional extruder.

2) Food grade 304 stainless steel, no stop for adjusting or cutter replacing, with better hygienic and convenient.

3) Accurate positioning and head cutting system, ensures easy adjustment, maintenance for cut blades replacement.

4) High end water resistant and hard alloy, high torque, which ensures long service life for machine

Sample pictures of fortified rice production line:

Using twin screw Extrusion technology, taking broken rice as basic raw materials, finely milling and mixing with other elements, then after conditioning with water and steam, these flour will be re-granulated by extruder, and finally roasted with low temperature. This fortified rice processing line produces rice, artificial rice products with unique sizes, shapes, taste and color, which is rich in scientific nutritional ratio and digestibility. The final artificial rice products is popular is Indian and Indonesian market.