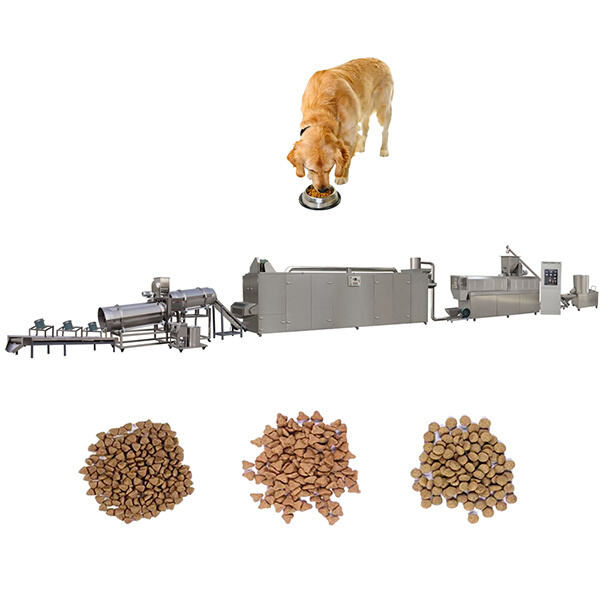

¿Has considerado alguna vez cómo se hace la comida de tu perro? Todo comienza en la fábrica de alimentos para perros, donde muchas recetas se combinan para crear una comida lo suficientemente saludable y agradable para nuestros bebés peludos favoritos. Esto es para darte una idea de cómo se fabrica la comida para perros y qué ocurre en la fábrica. maquina para hacer alimento para perros desde Jinan MT.

Los trabajadores están ocupados todo el día en la fábrica de alimentos para perros. La máquina para hacer comida seca para perros en Jinan MT se realizan tareas importantes como mezclar los ingredientes, cocinar y luego empaquetarlos hermosamente en una bolsa. Los materiales básicos son la forma más simple de los ingredientes que constituyen un alimento y, por lo tanto, es donde comienza cada proceso. Estos incluyen carne, granos, verduras y vitaminas. Se seleccionan después de mucha investigación para asegurarse de que la comida no sea dañina para los perros y, al mismo tiempo, los mantenga sanos.

Aquí, en la fábrica de alimentos para perros, la seguridad y la calidad se toman muy en serio. Siguen un régimen estricto y un protocolo que garantiza que las comidas no estén contaminadas con bacterias o químicos nocivos. Esto los hará más cautelosos mientras preparan las comidas. También inspeccionan los lugares mágicos donde se fabrica la comida para nuestras mascotas queridas y debemos admitirlo: ¿sana?! Esto asegura que cada bolsa de alimento para perros sea segura para su consumo, así que opta por Precio de la máquina para hacer alimento para perros desde Jinan MT.

El mundo de la comida para perros está en constante cambio y adaptación, con mucha ayuda de la nueva tecnología. Máquinas especiales y programas de computadora en la fábrica nos permiten generar nuevas variedades de comida para perros, así como mejorar los productos existentes. Por ejemplo, Máquinas de procesamiento de alimentos para mascotas mezclar los ingredientes correctos en el momento adecuado usando una computadora y monitorear cuidadosamente los tiempos de cocción. Esta tecnología asegura que cada bolsa de comida para perros sea de máxima calidad. Usar estas herramientas asegura que los trabajadores puedan elaborar una comida adecuada para diversos perros.

Una forma de hacer la comida es considerar pasos críticos para alimentar a los perros. Esta comida se produce en la fábrica siguiendo lo que los perros requieren. Estas consideraciones incluirían su edad, peso, niveles de actividad y más. Un software de computadora especialmente diseñado permite a los trabajadores mezclar los ingredientes para que su oferta de comida sea equilibrada y saludable. Una vez que todo está combinado, los ingredientes se cocinan en un solo plato delicioso. Luego, la comida se cocina y se coloca en bolsas, que son enviadas para ser vendidas en tiendas. máquina para hacer comida para mascotas .

Contamos con una planta procesadora de alimentos para perros de 20 años y poseemos numerosas patentes para máquinas de extrusión de alimentos y proyectos, incluido un sistema de secado de baja potencia con múltiples opciones y un sistema de extrusión de alta precisión patentado, equipo de aplanamiento de maíz con patente pendiente, sistema completamente automatizado de envasado y apilado patentado. Podemos proporcionar fórmulas para la instalación, puesta en marcha y capacitación de operadores, hasta que estés completamente satisfecho con los productos que producimos. En comparación con nuestros competidores, nuestro producto es de alta eficiencia, ahorra energía, tiene una calidad superior, precio competitivo y un servicio completo antes y después de la venta.

Cadena de suministro y capacidad de producción sólidas, así como una variedad de plantas de procesamiento de alimentos para perros. Flexibles y capaces de proporcionar servicios diseñados a medida. Estándares rigurosos e independientes y procedimientos de auditoría.

MT Machinery proporciona servicio posventa a clientes internacionales para plantas de procesamiento de alimentos para perros, incluyendo respuestas rápidas, comunicación clara y fluida, soporte técnico asegurando que cualquier problema se resuelva eficientemente con un equipo experimentado que ayuda a resolver consultas o problemas ofreciendo soluciones rápidas y efectivas. Un enfoque proactivo en el servicio ha llevado a un impresionante aumento en la satisfacción de los clientes, consolidando su reputación como socio de confianza en el comercio internacional. MT Machinery está comprometida en proporcionar el mejor servicio y apoyo posible a sus clientes, centrándose en sus necesidades y manteniendo canales de comunicación abiertos. Este compromiso con servicios excepcionales posventa no solo mejora la experiencia de compra de los clientes, sino que también ayuda a construir relaciones duraderas de cooperación con ellos.

Especializados en extrusiones de plantas de procesamiento de alimentos para RD y perros, con más de 15 años de historia y una fábrica de 20000m2. Nuestro equipo nos ha dado un buen posicionamiento en el mercado. Ofrecemos un servicio llave en mano completo, desde el proceso de materia prima hasta el sistema de embalaje, que incluye el sistema de control MCC. Toda la línea de procesamiento tiene un grado extremadamente alto de productividad y automatización. Es posible personalizar el proceso según la solicitud del cliente.