Kurkure cheetos nik naks are special extruded snacks, characterized with crunchy and good taste. They are made by a special extrusion process. The corn grits are moisturized in flour mixer with water, and then fed to the rotary head Extruder. In the extruder, duce to the two rotary plates, the corn grits are squeezed and twisted to curls shapes. The cutting knifes can cut into required lengths. The Kurkure/ Cheetos are fried in cooking oil or tasted in oven and then cooled before flavored. Seasoning is sprayed on the surface to achieve different favorable tastes. Due to the delicious flavors and nutrition, it is quite popular in market.

Features of kurkure cheetos making machine:

1) We can offer customers packing machine for this cheetos kurkure nik naks processing line. Its special extrusion technology.

2) Final products--kurkure cheetos nik naks snacks will be twisted, contains abundant compound carbohydrates and dietary fibre, micro-elements.

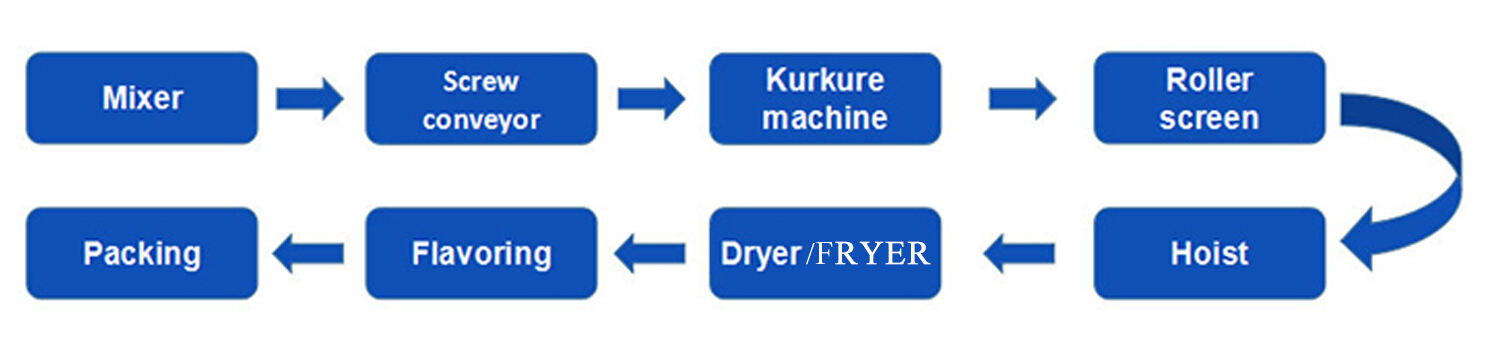

Process flow of kurkure cheetos making machine:

With OEM and ODM design, we promise to offer customers suitable proposal according to his factory size, which includes factory layout, Production line drawing, Turn-key solution from material grinding to final packing system.

Technical parameters of kurkure cheetos making machine:

| Model | Installed power | Power consumption | Capacity | Dimension (mm) |

| MTKC-IF cheetos making machine | 84KW | 59KW | 120-150KG/HR | 21000x1200x2200mm |

| MTKC-IIF cheetos making machine | 132KW | 92KW | 200-250KG/HR | 23000x1500x2200mm |

Sample pictures of kurkure cheetos making machine:

Extruded cheetos kurkure snack food processing line can produce flavored baking cheetos, nik naks and frying type cheetos, kurkure. After adding color agents and flavoring, very unique taste kurkure will be met. This production line characterizes with reasonable structural design, special material, self- cleaning