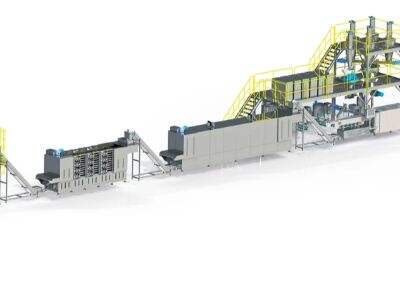

Quality and safety as well as the manufacturing process are all key considerations when it comes to making pet food. Pet owners are looking to provide their pets with the highest quality of food they can. This is the reason for the use of twin screw extruders in the manufacture of pet food by most of the companies. One of such companies is Jinan MT, due to the numerous advantages and characteristics of our machines, after many pet food pellets processing, along with the better in-noise pet food.

Double Screw Extrusion for Fast, Reliable, and Documented-Lever Production

A twin screw extruder is a machine to mix and cook various ingredients to produce pet food This machine does a good job of making sure that happens. This means it can handle many ingredients simultaneously, which reduces the time it takes for companies to produce more pet food. Companies can produce 100 tons of pet food with the help of suitable twin screw extruder from Jinan MT quickly and conveniently.

Pet food consistency is also extremely critical to the pet food manufacture. You have parameters such as temp, pressure, and mixing which can be controlled in a twin screw extruder. This control ensures that the pet food is uniform each time it is manufactured. And the pet owners wants to trust the food they offer to their fluffy friends, consistency of the quality achieves it.

Better Quality and Nutritional Value of Pet Food

Twin screw extruders of Jinan MT produce nutrition and delicious pet food as well. It can manufacture pet food in various shapes and sizes. The varieties offered can help create more fun food for your pet because pets will typically enjoy food that looks fun, colorful, and interesting.

Additionally, the cooking process within a twin screw extruder enhances the digestibility of the ingredient for pets. Because pets can better absorb the nutrients from food that is easier to digest. This equates to a healthier overall dog or cat and the energy to play and be active. Pets need proper nutrition to be healthy and happy.

Save on Production Costs through Twin Screw Extrusion Processing

In the long run, companies would then have a more cost effective and time saving solution with the use of a twin screw extruder from Jinan MT. The aim is less wastage because the machine efficiently utilizes all the components. If businesses minimize what they waste, they will save more money and reallocate the budget to other critical resources.

Not to forget, as we said above, the consistent production leads to lesser mistakes or defects in the pet food. They also mean that businesses need to spend much less time or money fixing issues when there are fewer errors. It saves more money for the company which can be given away to customers.

Twinscrew Extruder Technology with Wide Application Flexibility for Pet Food

Jinan MT also produces some other good features in this range of twin screw extruder help in adjusting and adapting to different processes. That means, these machines can be used to produce various kinds of pet food with different ingredients.

For instance, a company could utilize our machines to produce both of the kinds of pet food, dry and wet. It gives companies the ability to produce lots of different products for many different types of pets. Another aspect is that you can change the protein source used, the No.01 can also extrude chicken, beef or fish protein, as well as different types of grains and vegetables. This flexibility enables companies to develop various types of pet foods.

Twin Screw Extrusion to Improve Pet Food Safety and Shelf Life

Ultimately, pet food safety and shelf life of pet food are incredibly important issues in the pet food industry. Jinan MT's twin screw extruders solves both of these concerns well.

Because of the very high cooking temperatures reached in a twin screw extruder, this process also serves to lessen bacteria and other pathogens. That means the pet food is free from safety issues when the pets are eating it and the pet owner is free from worries.

The cooking process associates with the health of pet food and makes the shelf life of pet food longer besides safety. This enables businesses to create larger quantities of food and keep it for more extended periods before it spoils. Companies also want longer shelf life because of efficient storage and distribution is good for customers as well.

Table of Contents

- Double Screw Extrusion for Fast, Reliable, and Documented-Lever Production

- Better Quality and Nutritional Value of Pet Food

- Save on Production Costs through Twin Screw Extrusion Processing

- Twinscrew Extruder Technology with Wide Application Flexibility for Pet Food

- Twin Screw Extrusion to Improve Pet Food Safety and Shelf Life

EN

EN

AR

AR

BG

BG

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

ID

ID

SR

SR

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

HY

HY

LA

LA

KK

KK

UZ

UZ

KY

KY