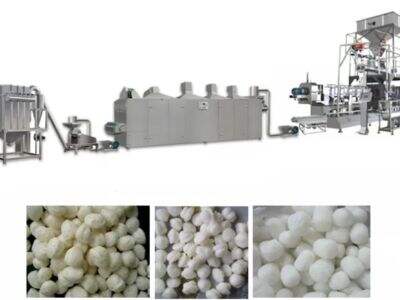

Jinan M.T. is a food equipment made which aims at accustomed your applicant with the advent new and agitate technology. They have genius inventions like the snack twin screw extrusion line. A game-changer in snack production and creation, this incredible technology has enhanced the ease and functionality of the process, which can radically transform how we see snacking.

Snacks used to take ages and had loads of manual work involved before the twin screw extrusion and it still holds good. But the whole project required a considerable effort from several individuals and each snack needed a lot of time to be refined. However, making snacks is easier nowadays, due to the advanced machine from Jinan MT. That means food manufacturers can spend less time and money while creating their tasty treats.

Healthy Snacks With Suitable Texture

The twin screw extrusion technology also has one of the advantages; the snacks got a texture that everyone loves. Two counter-rotating screws in this machine combine the ingredients thoroughly. It turns this into a uniform paste that can be easily moulded into our favourite snacks.

This technology provides the ability to produce several types of snacks such as cheese puffs, pretzels, and other delicious snacks. Snacks made using this process have a good sheen, appetizing color, and the crunch that consumers desire. The pieces, of course, are fortified by the twin screw extrusion technology which ensures longer shelf life and lowest breakage during transport to shops.

Accelerating and Improving Snack Production

The unique thing about twin screw extrusion technology is its precision and high controllability. The Jinan MT machine can be played to produce pastry of various shapes, sizes, and textures. This allows snack makers to create a variety of products catering to the tastes of their consumers.

The machine could equally regulate key variables such as temperature, moisture content and mixing period. Thanks to this meticulous control of those variables, the technology ensures identical, high-quality snacks in every batch. This especially matters for snack makers, since having consistent texture and flavor builds trust with their consumers. In addition, the extruder is able to operate in a 24/7 function, which can make snack production faster and harder than before.

A New Way to Make Snacks

Also: Jinan MT's twin screw extrusion technology is a game changer, not only for snacks, but for other food products as well. This technology enables the production of cereals, pasta, and even pet food, among others. That versatility makes it an invaluable tool for the majority of food manufacturers.

Additionally, this option is eco-friendly. Genetic Engineering, because it creates less waste and consume less energy than traditional food manufacture processes. Which means that it not only aids in making life easier for food manufacturing companies to make more, but it also reduces the pressure that we put on the environment. Then redeem themselves through success, which is a win-win for everyone.

Changing the Snack World

Snack food is a highly competitive arena with manufacturers always in search of innovative niches to differentiate themselves from the competition. Jinan MT twin screw extrusion technology opens up a world of possibilities for snack makers by enabling the production of snacks with distinctive textures flavors and looks. This innovation in turn attracts more clients and retains their interest.

It also helps snack producers create new and innovative products that resonate with rapidly changing consumer preferences. Because Jinan MT's top snack line could make snack producers switch to be in-line with consumers demand. This adaptability allows them to push more snacks and make more money.

EN

EN

AR

AR

BG

BG

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

ID

ID

SR

SR

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

HY

HY

LA

LA

KK

KK

UZ

UZ

KY

KY