Czy kiedykolwiek zastanawiałeś się, jak Twoje ulubione przekąski lub śniadaniówki są produkowane? To całkiem interesujące! Jednym z kluczowych urządzeń umożliwiających to jest ekstruder dwuosobowy. Prawidłowa maszyna o wielkim znaczeniu przygotowuje pokarm do różnych celów i pozwala firmom na przetwarzanie i produkcję jakościwnych produktów w podobnych tempach i użyciu.

Jinan MT projektuje unikalne ekstrudery dwuosobowe w Jinan MT i pomaga naszym klientom w zwiększaniu ich produktywności. Ta maszyna służy do ułatwienia przygotowania przekąsek; w tym artykule dowiemy się więcej o tej maszynie i jak może ona produkować przekąski bardziej wygodnie i szybciej.

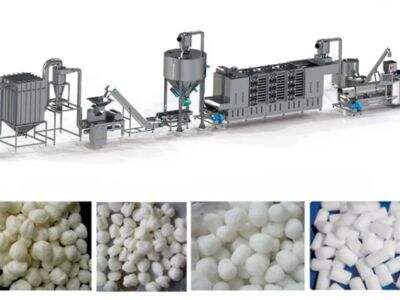

Używanie ekstruderów dwuosobowych do produkcji dodatkowych przekąsek

Ekstrudery dwuskrzynkowe są również niesamowite, ponieważ mają zdolność do wyprodukowania dużej liczby przekąsek w ograniczonym okresie czasu. Oznacza to również, że producenci mogą skalować produkcję swoich pysznych produktów. Dwuskrzynkowy ekstruder jest szybki i może produkować więcej przekąsek w krótkim czasie, co sprawia, że jest on odpowiedni dla innych potrzeb fabrycznych.

Dwuskrzynkowy ekstruder ma parę połączonych śrub, które przenoszą dodatki do żywności przez urządzenie. Te wymagają specjalnego rodzaju śruby do mieszania składników. Ponieważ składniki są tak jednostajnie mieszane, przekąski wychodzą gładkie i pyszne. Nikt nie chce, aby jego przekąski były grudkowate lub nierówne, więc to jest ważne.

Tworzenie pysznych przekąsek o świetnej jakości

Ważną zaletą ekstrudera z dwiema śrubami jest to, że produkuje spójne w smaku przekąski. Odpowiada to spójności, która jest cechą charakterystyczną każdego przekąskowego produktu do spożycia i prezentacji. Ma określone kontrolki, które pozwalają utrzymać jakość podczas procesu, co gwarantuje, że każda partia przekąsek będzie wybuchowała smakiem.

Ekstruder z dwiema śrubami zapewnia, że wszystkie składniki są dobrze wymieszone. To unika powstawania grudek lub nierównych porcji w kawałkach, które mogłyby nadać im nieprzyjemny smak. Ponieważ są produkowane za pomocą ekstrudera z dwiema śrubami, możesz być pewien, że będą miały ten sam wyśmienity smak i teksturę za każdym razem, gdy je jesz.

Pracując lepiej i szybciej

Zwiększone efektywności: Oprócz tworzenia większej liczby przekąsek i utrzymywania ich smakowitości, ekstrudery z dwiema śrubami pomagają firmom działać bardziej efektywnie. Ponieważ te maszyny mogą działać przez dłuższe okresy czasu, pozwala to na produkcję większej liczby przekąsek przy mniejszym czasie simplyfikacji. Co jest świetne, ponieważ pomaga wobec wysokiego popytu na przekąski.

Jak wspomniano, istnieje jeszcze jedna zaleta ekstruderów z dwiema śrubami, która polega na tym, że są łatwe do czyszczenia. Maszyna może być szybko wyczyszczona po przygotowaniu partii przekąsek, dzięki czemu będzie gotowa do użytku w krótkim czasie. Ponieważ oszczędza to sporo czasu i sprawia, że produkcja przebiega dużo płynniej, pracownicy mogą skupić się na produkowaniu większej ilości przekąsek.

Ułatwianie procesu

A kolejną dużą zaletą jest fakt, że ekstruder z dwiema śrubami może uprościć całą produkcję przekąsek (w porównaniu do tradycyjnego procesu). Jest on stosowany do przetwarzania szerokiego spektrum surowców, co czyni go odpowiednim do produkcji różnych przekąsek, kawy czy pokarmów dla zwierząt. Tylko jedna jednostka pomaga ci wyprodukować wiele rodzajów przekąsek.

Zamiast potrzebować wielu maszyn dla każdego z etapów w procesie, ekstrudera dwuskrzyniowa może wykonywać wiele zadań jednocześnie. Pozwala to zaoszczędzić czas i wysiłek w zakładzie produkcyjnym. Dzięki tej uproszczeniu firmy mogą działać bardziej efektywnie i skupiać się wyłącznie na produkcji smacznych przekąsek dla nas wszystkich.

Uzyskiwanie większej kontroli nad składnikami

Na koniec, ekstrudery dwuskrzyniowe kontrolują transport składników przez maszynę. Są wyposażone w czujniki i systemy sterujące, które zapewniają ich połączenie w odpowiednich proporcjach. Co pomoże zagwarantować, że ostateczny produkt będzie odpowiadał wymaganym standardom jakości.

Ekstrudera dwuskrzyniowa umożliwia dostosowywanie różnych parametrów, aby uzyskać pożądane produkty przekąskowe. Na przykład zmieniając temperaturę lub prędkość maszyny, aby osiągnąć odpowiednią teksturę i smak. Ta elastyczność ma ogromne znaczenie dla-produkcji przekąsek wysokiej jakości, preferowanych przez konsumentów.

EN

EN

AR

AR

BG

BG

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

ID

ID

SR

SR

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

HY

HY

LA

LA

KK

KK

UZ

UZ

KY

KY