Ever wonder what goes into making dry food for your pets? Before it even reaches your pet's dish, the content is transported on a lengthy journey. It is a Jinan MT multi-step process to make this pet food machine food, with each step being equally essential part. Learn More – How is dry pet food manufactured?

Extrusion is the process used to make dry pet food. This pet food extruder machine literally means that the ingredients are heated and pressed into tiny bits — kibble. This is the job of a special machine called an extruder. This Jinan MT is heating up so the ingredients are warm and soft. The kibble is then forced through a small hole, called the die, to create familiarly shaped morsels. In doing so, This procedure also helps in ensuring that the food is cooked well and has a good texture to be consumed by pets.

It is very important to choose the best ingredients, as these will be essential in it being a dry pet food. The ingredients in homemade dog food must be safe and digestible for dogs. There are various sub-types of ingredients, which should be selected with care. The pet food extrusion machine quality control is essential as well. The idea behind the process is that all of what the pet eats are fresh and good for her. The ingredients are used only after passing through a vigorous test to check if they are like when clause*)(I think this sentence is incomplete, is it?) This Jinan MT is what helps protect these family members and guarantees they receive good nutrition.

Once the dry pet food is made, it needs to be packed in a way that will keep it fresh for your pets consumption. Close the bags all too tightly when packaging up your food. It prevents air and moisture from getting in, which causes the food to spoil or become stale. This pet food processing machine includes keeping the food safe from other things that might make it go bad (bugs, moisture) It ensures that when you purchase dry pet food for your pet, it is fresh and delicious!

Healthy nutrition is necessary to keep pets healthy just as people require a proper diet. While dry pet food is designed by veterinarians to give pets the nutritional balance and energy they need for growth, play or activity. The ingredients are selected to harness the correct levels of protein, fat, fiber and other essential nutrients. This pet food making machine price balanced nutrition aides in keeping pets healthy and happy! Healthy diet makes pets more energetic to play and be physically active, which is essential for their well being.

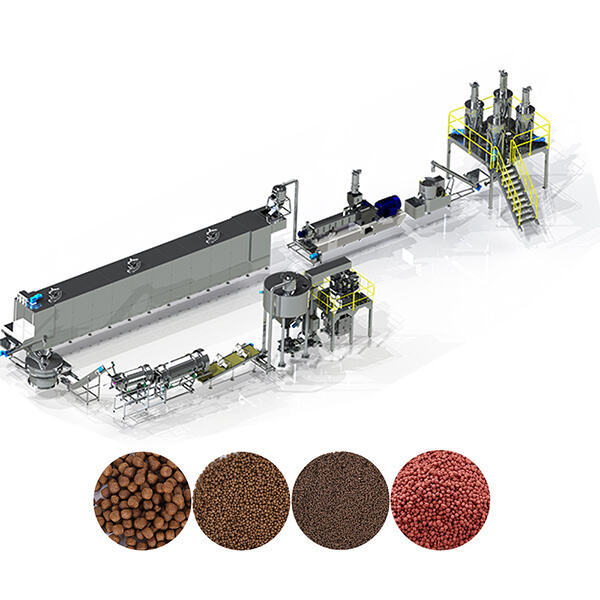

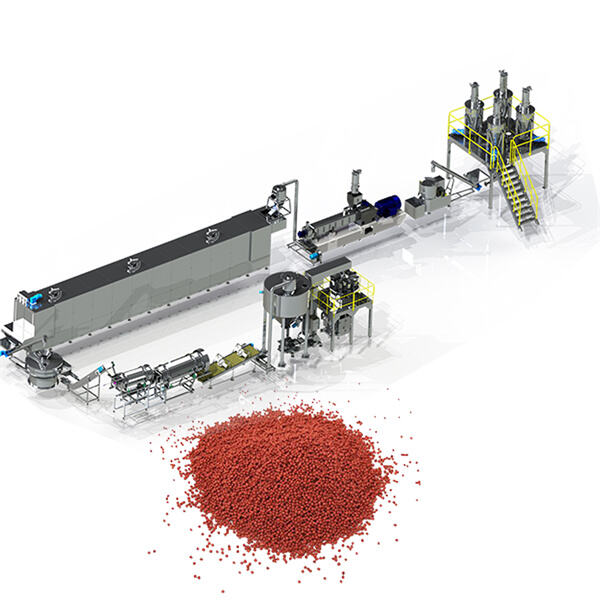

Dry pet food manufacturing process in RD and food extrusion projects with more than 15 years of history and a factory of 20000m2, our machine gains great popularity on the market. We provide complete turnkey solutions from raw material to packing system, which includes MCC control system. The entire process line is significant productivity and automation. Any customization can be made according to the needs of the customer.

MT machinery provides outstanding after-sales service international customers includes prompt response times clear efficient communication technical support ensuring any issues Dry pet food manufacturing process quickly team dedicated professionals assist you any query issue arise providing quick efficient solutions proactive approach customer support led increase satisfaction customers consolidated status reliable partner international commerce focusing needs clients maintaining open line communication MT machinery ensures our clients receive best quality service support commitment excellent after-sales support only improves experience buying customer also promotes positive long-term cooperation them

A strong supply chain, large capacity of production, and a selection of extrusion equipment for food are all strengths. Can provide Dry pet food manufacturing process solutions and a lot of flexibility. Strict and reliable standards, as well as Audit mechanisms.

With more than Dry pet food manufacturing process experience of our engineering team, we own several patents pertaining to special food extrusion machinery and projects like multi-choice, low energy-intensive drying system, high-precision food extrusion systems and a unique corn flattening machine fully automated stacking and packing system, etc.We offer production formulas, installation, debugging and operator training service until satisfied that the product can be made.In comparison to our competitors, our product offers the highest efficiency, energy savings superior quality, competitive price, and a complete service prior to and after the sale.